Armstrong Series FSA

Unit humidifiers for area humidification

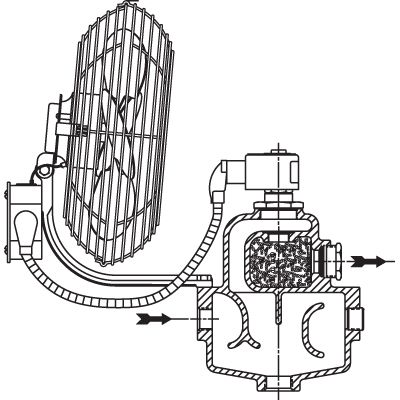

How does it work

The steam is initially put through an in-line strainer to remove larger solid particles and then fed into the separator chamber. This section contains two baffles which reduce the speed of the steam (then the noise) and reverse its flow in order to separate the condensation from the steam. Steam from the separating chamber flows around and through the solenoid valve, which is actuated by a demand signal from the humidistat. Next the steam flows into the drying chamber, dispersion is through a jet nozzle or by a fan.

Features

The humidifier with solenoid valve, standard open contact humidistat, « Y » type strainer, Armstrong inverted bucket trap and temperature sitch to prevent « spitting » during warm-up.

Available in 2 types of control:

- Electric model - EM type

- Pneumatical model - AM type

Maximal steam pressure is 4 bars and steam capacity is 135 kg/h.

Options

- Fan and motor for FSA model